-

CNC Laser Cutting Parts

-

CNC Laser Cutting Sheet

-

CNC Laser Cutting Stainless Steel

-

CNC Laser Cutting Metal

-

CNC Plasma Parts

-

Metal Bending Parts

-

Metal Plate Rolling

-

Metal Fabrication Parts

-

Punching Metal Parts

-

Steel Fabrication Parts

-

Aluminium Fabrication Parts

-

Aluminum Sheet Rolling

-

Welding Metal Parts

-

Painting Metal Parts

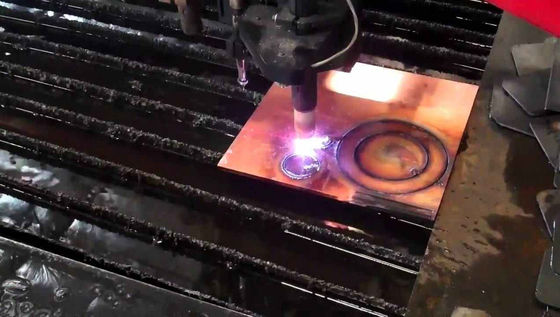

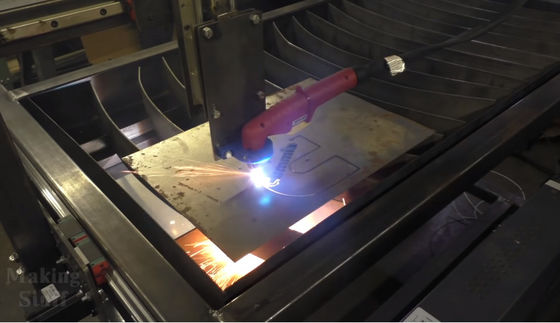

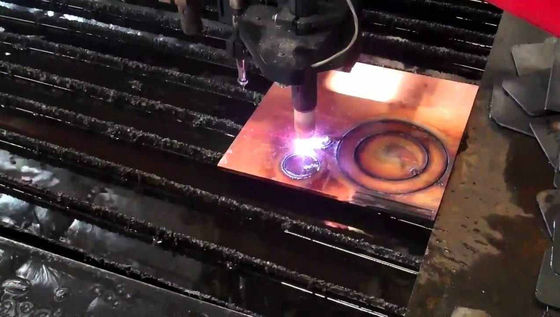

CNC Plasma Cutting Copper/Aluminum/Stainless Sheet/Mild Steel High Speed

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Technics | CNC Plasma | Size | Customized Size |

|---|---|---|---|

| Material | Stainless Steel Sheet/Alumin | Thickness | 5mm-20mm |

| Certification | ISO9001 | OEM | Accept |

| Tolerance | ±1% | Delivery Time | 7-15days |

| Highlight | Plasma Cutting Service,cnc plasma cutting aluminum plate |

||

CNC Plasma Cutting Copper/Aluminum/Stainless Sheet/Mild Steel High Speed

Production Introduction

Plasma cutting method is to use the heat that generated from high temperature plasma electric arc to cut the steel parts. During cutting processes, metal material will be melting and evaporated, then to use plasma power to erase the metal melting fusions.

The plasma cutting process involves using heat to melt a metal instead of mechanical cutting. Plasma cutters work by sending an electric arc through a gas. This gas then passes through a constricted opening (nozzle). The restricted opening causes the gases to squeeze through it at high speed, forming plasma. Cutting a workpiece entails subjecting the cutting tip of the plasma cutter to the workpiece. Also note that due to the conductivity of plasma, there is a need to connect the workpiece to the ground through the cutting table.

Plasma cutting is a process that involves the use of the fourth stage of matter to cut conductive metals. This process offers many advantages, including higher productivity, versatility, precision, and surface quality.

| Material Thickness | Plasma Gas | Secondary Gas | Remark |

| Structural Steel 0.5 to 8mm | Oxygen | Oxygen or oxygen/ nitrogen or nitrogen | Burr-free edges can tolerate square-ness, with smoothness akin to laser cutting |

| Structural Steel 4 to 50mm | Oxygen | Oxygen/nitrogen or nitrogen or air | Burr free up to 20mm, the cut surface has a smooth appearance, up to 25mm square-ness tolerance, akin to laser cutting |

| High-alloy steel 5 to 45mm | Argon / Hydrogen / Nitrogen | Nitrogen or Nitrogen/hydrogen | Burr free up to 20mm, smooth cuts, poor tolerance for square-ness |

| Aluminum 1 to 6mm | Compressed Air | Nitrogen or Nitrogen/hydrogen | Burr-free cuts, the surface could be rough or grainy, allowing nearly vertical cuts |

| Aluminum 5 to 40mm | Argon / Hydrogen / Nitrogen | Nitrogen or Nitrogen/hydrogen | Burr free up to 20mm, grainy or rough surface, allows nearly vertical cuts |

Production Show

![]()

![]()

Workshop Show

![]()

Packing & Delivery

![]()

![]()

FAQ

1. What are your main products?

We specialize in manufacturing metal stamping die, metal stamping parts, sheet metal parts, CNC machining part and welding structural parts etc.

2. What is surface treatment do you have?

Powder coating, zinc plating, polished, paint, anodic oxidation etc.

3. Can I get the samples?

Yes, the sample is free, you only need to bear express shipping freight or we can send the sample to you by your collect account.

4. What is the MOQ?

The MOQ is 500pcs for large parts, and 1000pcs for small parts.

5. What’s the delivery time?

Normally, it will take about 20- 25 days to finish one order.

6. What’s your payment term?

30% down payment, 70% before shipment

7. Do you receive OEM/ODM?

Yes. We receive OEM/ODM.