-

CNC Laser Cutting Parts

-

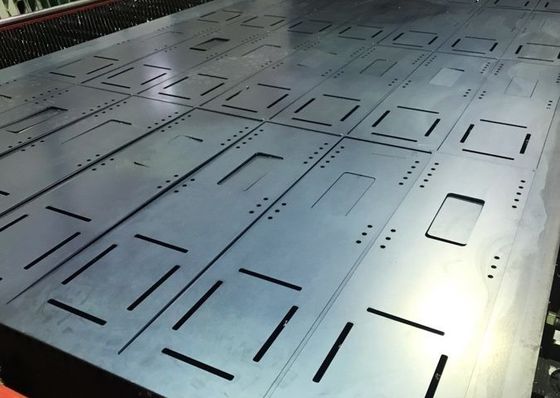

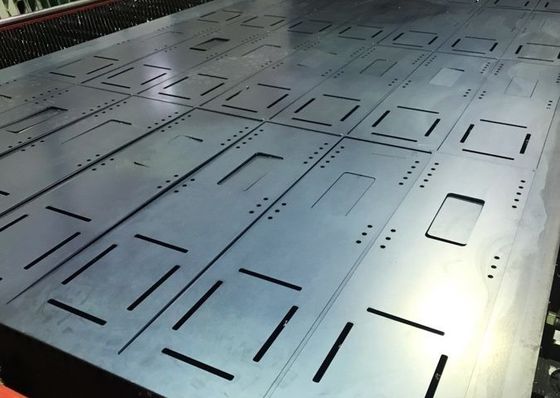

CNC Laser Cutting Sheet

-

CNC Laser Cutting Stainless Steel

-

CNC Laser Cutting Metal

-

CNC Plasma Parts

-

Metal Bending Parts

-

Metal Plate Rolling

-

Metal Fabrication Parts

-

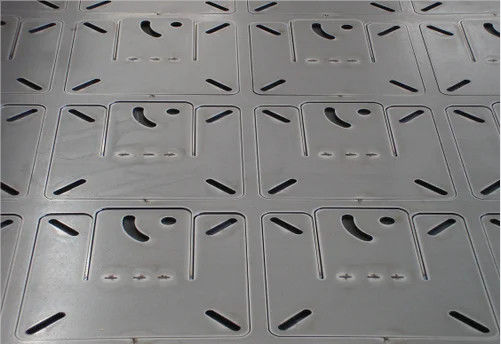

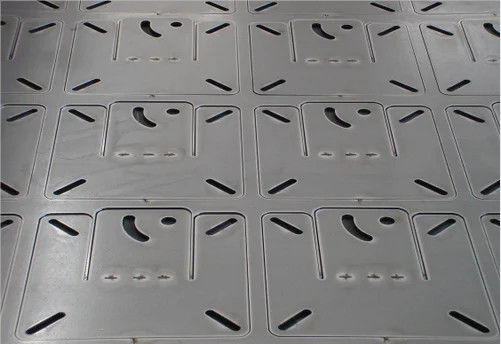

Punching Metal Parts

-

Steel Fabrication Parts

-

Aluminium Fabrication Parts

-

Aluminum Sheet Rolling

-

Welding Metal Parts

-

Painting Metal Parts

ISO9001 0.1mm CNC Iron Sheet Metal Bending CNC Cutting Plasma Cutting Services

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Technique | CNC Laser Cutting | Drawing Format | CAD/Dwg Etc |

|---|---|---|---|

| Thickness | 0.1-20mm | Dimension | Customized Size |

| Positioning Accuracy | ±0.05mm | Control System | Cypcut |

| Repeatability Accuracy | ±0.03mm | Material | Aluminum, Brass, Bronze, Copper |

| Highlight | ISO9001 sheet metal bending,0.1mm sheet metal bending,CNC cutting plasma cutting services |

||

ISO Certificated CNC Laser Cutting Iron/Sheet Metal Bending Sample Available

Products Description

Computer Numerical Control (CNC) laser cutting commonly uses optics, an assist gas, and a guidance system to direct and focus the laser beam into the workpiece. The many benefits of CNC laser cutting include: Speed. Less waste. Broad range of materials.

Laser Cutting is a method for transforming a 2D file into a physical object. This technology can be performed on different materials such as plastic, wood and cardboard. Laser Cutting involves cutting the material with a highly accurate laser that focuses on a small area of material. It can cut it with a thickness up to 10mm. There are different types of lasers which can be pulsed or continuous. We use continuous laser cutters that can cut all types of materials with a higher speed than the pulsed laser cutters can.

| Name | Detail | Optional |

| Material | GB, JIS, ASTM, DIN, AISI.EN,AS. | Carbon steel, SPCC, SGCC, Stainless steel, Aluminum, Brass, Copper, Titanium Alloy, Nylon, Acrylic, UHMWPE, PVC etc. |

| Shape | Plate, Tube, Rod. | |

| Processings | Accept | Laser Cutting, Precision Stamping, CNC Bending, CNC Milling, CNC Turning, Threading, Riveting, Drilling, CNC Punching, Die Casting, Laser Welding etc |

| Surface Treatment | Accept | Brushing, Polishing, Vacuum Plating, Anodizing, Powder Coating, Zinc Plating, Chrome Plating, Nickel Plating, Tin plating etc |

| logo | Accept | Silk print, Laser marking, UV print, Multicolor pad printing. |

| Size | 160*200*150mm. | Accept custom size. |

| Color | RAL , Pantone, RGB, CMYK. | White, black,silver, red, grey etc |

| Software | CAD, Solidworks, CATIA, UG, PRO-E. Inventor, AI | |

| Drawing format | DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI,PDF, JPG, Draft. | |

| Sample lead time |

No surface treatment, 1-3 workdays. Require surface treatment, 3-5 workdays. |

|

| Pricing Term | FOB, CIF, DDP etc | |

| Port of Loading | Shanghai or Ningbo | |

| Payment term |

TT (30% in advance as deposit, balance before delivery) , L/C, trade assurance order etc. Cost under 5000USD 100% prepay. |

|

Details Photos

![]()

![]()

![]()

![]()

Our Services Process:

Quotation: We promise your inquiry of stainless steel laser cutting parts can be quoted within 6 hours as long as we confirm your drawing and requirements.

Sample Making: It is fastest within 3 days.

Mass Production: During production, we can give you updates by sending you real pictures and videos of stainless steel laser cutting parts.

Packaging: Packaging assure to be 100% safe and stable.

After-sales Service: Once you receive the stainless steel laser cutting parts, please open the packaging and check all cargo within 7 days. If there are quality issues, we will arrange to remake or return money for you.

Packing & Shipping

Fine and safe packaging used for your products to assure no any damages during transportation.

1. Standard export packaging:

PE film coating+Waterproof plastic film+Wooden Pallet or Wooden Case;

2. Customized packaging as your request (Logo or other contents accepted to be printed on the packaging);

3. Other special packaging will be designed as customer’s request;

4. By International Express: DHL/UPS/FEDEX and our own express line;

5. By air or By sea.

![]()

![]()

![]()

FAQ:

-

Are you a trading company or a manufacturer?

We are factory, so we can offer you competitive price

What kind of services can you provide?

Our company (Yigang) can provide OEM sheet metal processing, CNC processing and manufacturing services.

What information is required for a quote?

A: In order to quote you earlier, please provide us with the following information when inquiring.

Detailed drawings (STEP , CAD , SOLID Works , PROE , DXF and PDF)

Material Requirements (Steel, Mild Steel, Carbon Steel, Stainless Steel, Copper, Aluminum, etc.)

Surface treatment (dusting, sandblasting, flocking, polishing, oxidation, wire drawing, etc.)

Quantity (per order/month/year)

Are there any special requirements or requirements, such as packaging, labeling, delivery, etc.

What if there are no drawings?

A: Please send your samples to our factory, then we can copy or offer you a better solution. Please send us pictures or sketches with dimensions (thickness, length, height, width), if you place an order, a CAD or 3D file will be made for you.